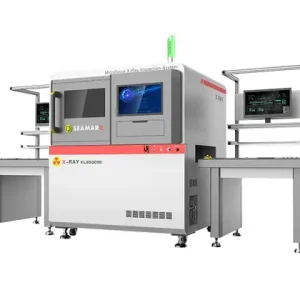

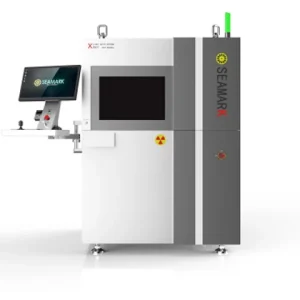

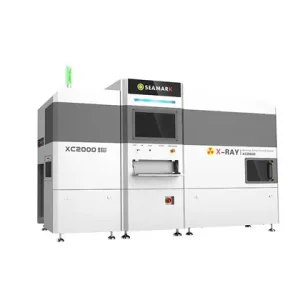

XB7200-Stacking Battery Inspection

The XB7200 is designed to perform fully automatic inline inspections of multi-layer stacking power batteries. It employs either TDI line scanning image technology or area array image acquisition technology. The inspection parameters it assesses include weight, angle overhang, large folds, and tab creases.

Product Information

Features of XB7200-Stacking Battery Inspection

- State-of-the-Art X-ray Technology The XB7200 is equipped with the highly regarded Hamamatsu X-ray tube, known for its exceptional precision. This technology enables the machine to conduct thorough inspections of winding batteries, maintaining superior performance levels.

- Proprietary Algorithm Expertise Seamark’s exclusive algorithm software enhances XB7200’s capabilities significantly. These advanced algorithms empower the machine to analyze intricate battery details accurately, ensuring precise and dependable quality assessments.

- Professional Customer Support Seamark offers unparalleled customer assistance. Its proficient research and development (R&D) experts and responsive after-sales service team provide rapid and effective solutions, guaranteeing uninterrupted operation for businesses relying on XB7200.

Specification of XB7200-Stacking Battery Inspection

| Equipment Size | 8500mm*3200mm*2800mm |

| Beat | ≥24PPM and above (2 or 4 angles) |

| Excellent Rate | ≥99.5% |

| Weighing | Measurement accuracy ≤0.01g, weight ≥5kg |

| Equipment Failure Rate (DT) | ≤2% |

| Overkill Rate | ≤1.5% |

| Underkill Rate | ≤0% |

| Repeated Test Accuracy | ≤40um (standard piece measurement) |

| Incoming Materials Method | Logistics line incoming materials |

| Radiation Safety Standard | ≤1μSV/hr |

| Inspection Content | Weighing, Overhang, large surface fold, tab fold, etc. |

| X-ray tube | Voltage: 40-90KV/40-130KV |

| Current | 10-200uA/10-300uA |

| Receiver | Line array camera TDI or flat panel detector. Changeover time: The changeover time for old varieties is ≤ 2 hours/person; the changeover time for new varieties is ≤ 4 hours/person. |

| Compatibility Range | Square aluminum shell: length: 80~220mm; width: 130~200mm; thickness: 10~25mm. |

| Blade Battery | Length 320~600mm; Width: 80~120mm; Thickness: 10~30mm |

Be the first to review “XB7200-Stacking Battery Inspection”

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.