CONTOUR MEASURING MACHINE

A Contour Measuring Machine (often called a “Contracer”) is a high-precision metrology instrument used to evaluate the 2D surface profiles and geometrical features of a part. It is particularly valuable for measuring intricate details like angles, radii, and distances that are difficult to capture with standard hand tools.

Product Information

- Contact Method (Traditional): A sensitive diamond-tipped stylus or probe traces along the workpiece’s surface. As the stylus moves up and down (Z-axis) while traversing horizontally (X-axis), the sensors record coordinate points.

- Non-Contact Method (2026 Trend): Modern systems, such as the Keyence VR-6000, use structured light, lasers, or optical sensors to capture wide-area 3D measurements in seconds without physical contact.

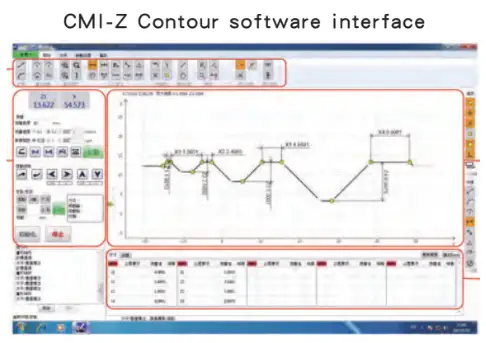

- Data Processing: Specialized software, such as CMM-Manager, processes the collected point data to compare the actual shape against nominal CAD designs.

- Combined Measurement: Many 2026 models integrate both contour and surface roughness measurement into a single device, such as the Mitutoyo Formtracer, saving time and reducing equipment costs.

- High Precision: Advanced machines offer sub-micron resolution (often as low as 0.016 µm) and high-speed drives reaching up to 80 mm/s.

- Automated Analysis: CNC-controlled machines allow for “one-click” automated measurement sequences, which are essential for high-volume production lines.

- Automotive: Inspecting the curvature and alignment of body panels, engine valves, and brake calipers.

- Aerospace: Verifying turbine blade profiles and fuselage panels for aerodynamic efficiency.

- Electronics: Analyzing semiconductor wafer flatness and circuit board surface accuracy.

- Medical Devices: Ensuring the exact surface contours of implants and surgical instruments for patient safety.

Be the first to review “CONTOUR MEASURING MACHINE”

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.