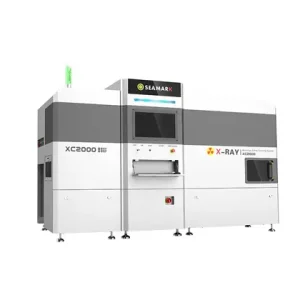

XB7100-Winding Battery Inspection

The XB7100 provides a fully automated inline inspection for multi-layer winding power batteries. It conducts a thorough examination of key elements in winding power and energy storage batteries, including the alignment of positive and negative electrode plates, large surface folds, and tab-pulling pins, thereby ensuring comprehensive quality control.

Product Information

Features of XB7100-Winding Battery Inspection

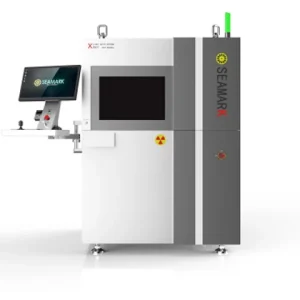

- Premium X-ray Technology XB7100 employs the highly acclaimed Hamamatsu X-ray tube, recognized globally for its superior quality and precision. This high-end X-ray technology ensures accurate and detailed inspections of winding batteries.

-

Cutting-Edge AlgorithmEquipped with Seamark’s self-developed algorithm software, XB7100 incorporates advanced algorithms for sophisticated analysis. This software enhances the machine’s ability to detect intricate details within batteries, contributing to precise quality assessments.

-

Expert SupportSeamark provides unmatched customer support with a dedicated team of professionals. Their experienced Research and Development (R&D) specialists and after-sales service team offer prompt and efficient solutions. This commitment ensures seamless operation and reliability for businesses relying on XB7100 Winding Battery Inspection machines.

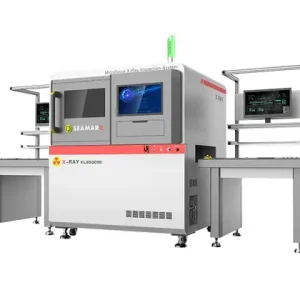

Specifications of XB7100-Winding Battery Inspection

| Equipment Size | 5460mm*2600mm*2800mm |

| Beat | ≥26PPM and above (2 angles or 4 angles) |

| Excellence Rate | ≥99.5% |

| Overkill Rate | ≤1% |

| Underkill Rate | ≤1% |

| Equipment Failure Rate (DT) | ≤2% |

| Repeated Test Accuracy | ≤40um (standard piece measurement) |

| Average Failure Interval (MT BT) | ≥8H |

| Method of Incoming Materials | Incoming materials from logistics line |

| Radiation Safety Standard | ≤1μSV/hr |

| X-ray Tube | Voltage: 40-90KV/40-130KV; Current: 1 0 – 2 0 0 u A / 1 0 – 3 0 0 u A |

| Receiver | Flat panel detector |

| Photo Taking Time | ≥0.7S |

| Model Change Time | The model change time of old varieties ≤ 2 hours/person; the model change time of new varieties ≤ 4 hours/person |

| Compatible Range | Height: 70~220mm; Width: 80~260mm; Thickness: 5~25mm (or customize all models on the market) |

| Inspection Content | Overhang, Large area fold, Tab fold |

Be the first to review “XB7100-Winding Battery Inspection”

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.