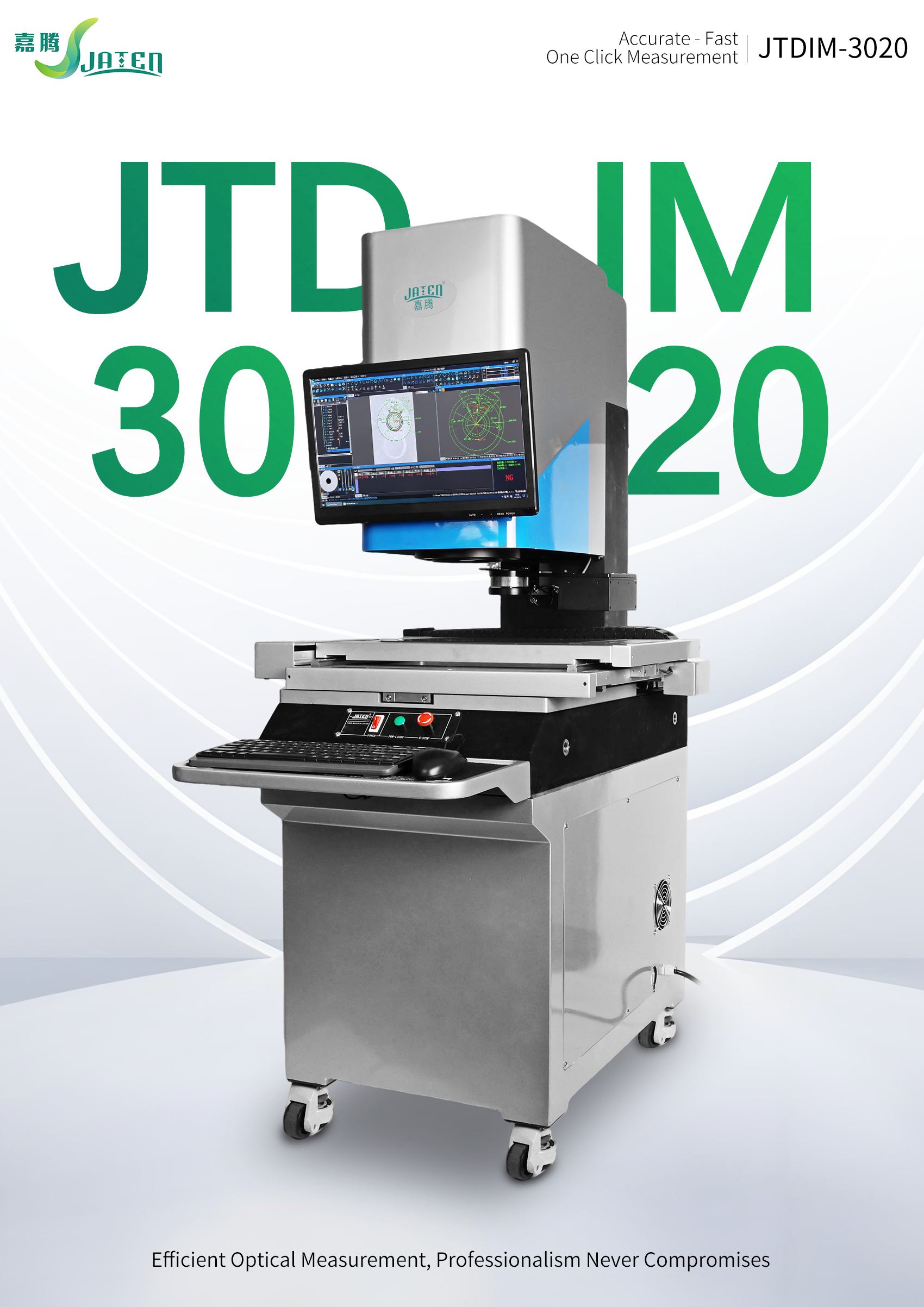

JTDIM3020-Efficient Optical Measurement

| Customization: | Available |

|---|---|

| After-sales Service: | Installation and Operation Training |

| Warranty: | 12 Months |

Thông tin sản phẩm

To meet the diverse requirements of our customers, we offer comprehensive product customization services, including functionality, dimensions, interfaces, and more. Feel free to contact us for detailed customization options.

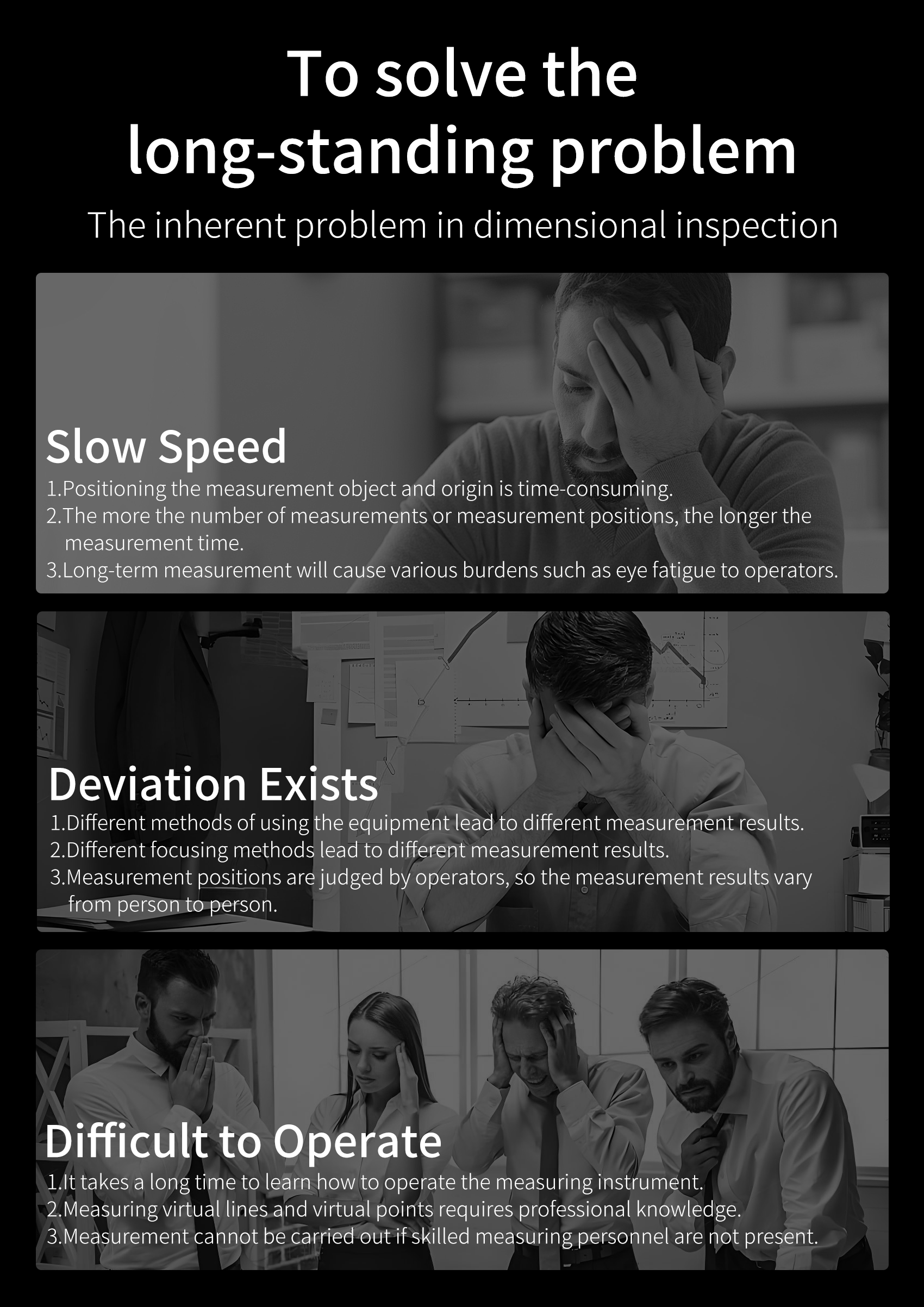

1. Solving Long-Standing Issues in Dimensional Inspection

Traditional dimensional measurement has faced persistent challenges that impact accuracy, repeatability, and workflow efficiency. Our solution is designed to address these fundamental problems.

2. Deviation Is Unavoidable in Manual Measurement

Different operation habits lead to inconsistent measurement results.

Variations in focusing methods cause noticeable differences in measurement outcomes.

Measurement points and positions rely on the operator’s judgment, resulting in person-to-person discrepancies.

3. Difficult to Operate and Highly Dependent on Skilled Personnel

Measuring instruments require long training time before operators can work independently.

Judging virtual lines and virtual points demands professional knowledge and experience.

Measurement cannot proceed efficiently without experienced operators on site.

1. Solving Long-Standing Issues in Dimensional Inspection

Traditional dimensional measurement has faced persistent challenges that impact accuracy, repeatability, and workflow efficiency. Our solution is designed to address these fundamental problems.

2. Deviation Is Unavoidable in Manual Measurement

Different operation habits lead to inconsistent measurement results.

Variations in focusing methods cause noticeable differences in measurement outcomes.

Measurement points and positions rely on the operator’s judgment, resulting in person-to-person discrepancies.

3. Difficult to Operate and Highly Dependent on Skilled Personnel

Measuring instruments require long training time before operators can work independently.

Judging virtual lines and virtual points demands professional knowledge and experience.

Measurement cannot proceed efficiently without experienced operators on site.

4.CREATE A NEW ERA OF MEASUREMENT:One-Button Rapid Flash Measuring System

Powered by a self-developed measurement algorithm and JATEN’s customized software, this system delivers fast, accurate, and repeatable results with minimal operator involvement.

4.CREATE A NEW ERA OF MEASUREMENT:One-Button Rapid Flash Measuring System

Powered by a self-developed measurement algorithm and JATEN’s customized software, this system delivers fast, accurate, and repeatable results with minimal operator involvement.

5.Four Key Highlights — Performance Upgraded Again

(1)JATEN Self-Developed Algorithm

Intelligent, worry-free operation that adapts automatically to various measurement scenarios.

(2)Mitsubishi Electric (Japan) Three-Axis Servo Drive System

High-precision positioning with outstanding stability and long-term reliability.

(3)JATEN Self-Developed Image Acquisition System

High-spec hardware delivers ultra-high resolution for clear, accurate image capture.

(4)JATEN Customized Software

Easy to learn and operate, enabling rapid setup and smooth user experience.

5.Four Key Highlights — Performance Upgraded Again

(1)JATEN Self-Developed Algorithm

Intelligent, worry-free operation that adapts automatically to various measurement scenarios.

(2)Mitsubishi Electric (Japan) Three-Axis Servo Drive System

High-precision positioning with outstanding stability and long-term reliability.

(3)JATEN Self-Developed Image Acquisition System

High-spec hardware delivers ultra-high resolution for clear, accurate image capture.

(4)JATEN Customized Software

Easy to learn and operate, enabling rapid setup and smooth user experience.

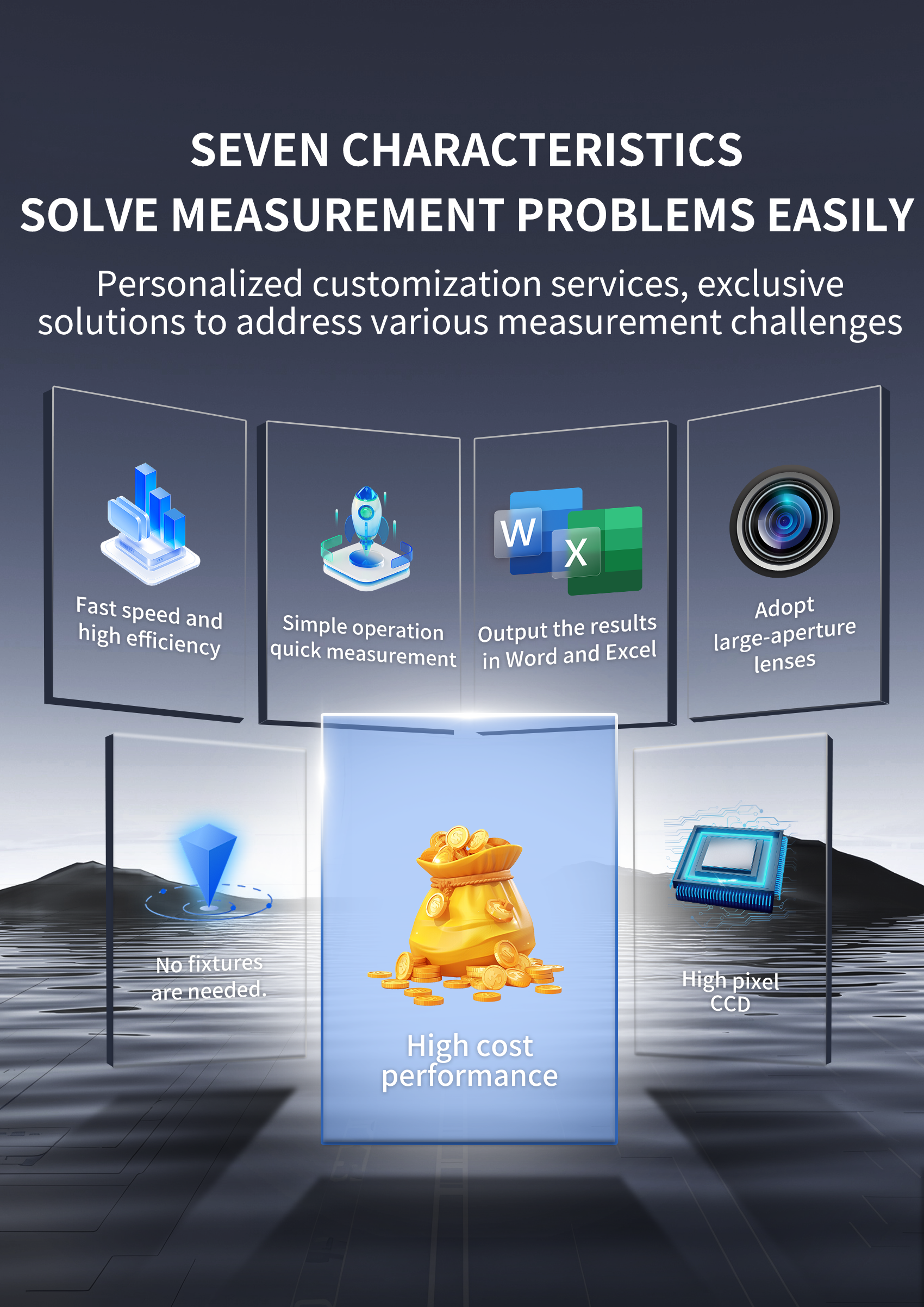

6.Seven Key Features — Effortlessly Solve Measurement Challenges

Providing personalized customization and tailored solutions to meet a wide range of measurement needs.

6.Seven Key Features — Effortlessly Solve Measurement Challenges

Providing personalized customization and tailored solutions to meet a wide range of measurement needs.

7.SUPER IMAGE MEASUREMENT

Measure multiple workpieces instantly, intelligently adapt to diverse scenarios, and open a new era of smart measurement.

7.SUPER IMAGE MEASUREMENT

Measure multiple workpieces instantly, intelligently adapt to diverse scenarios, and open a new era of smart measurement.

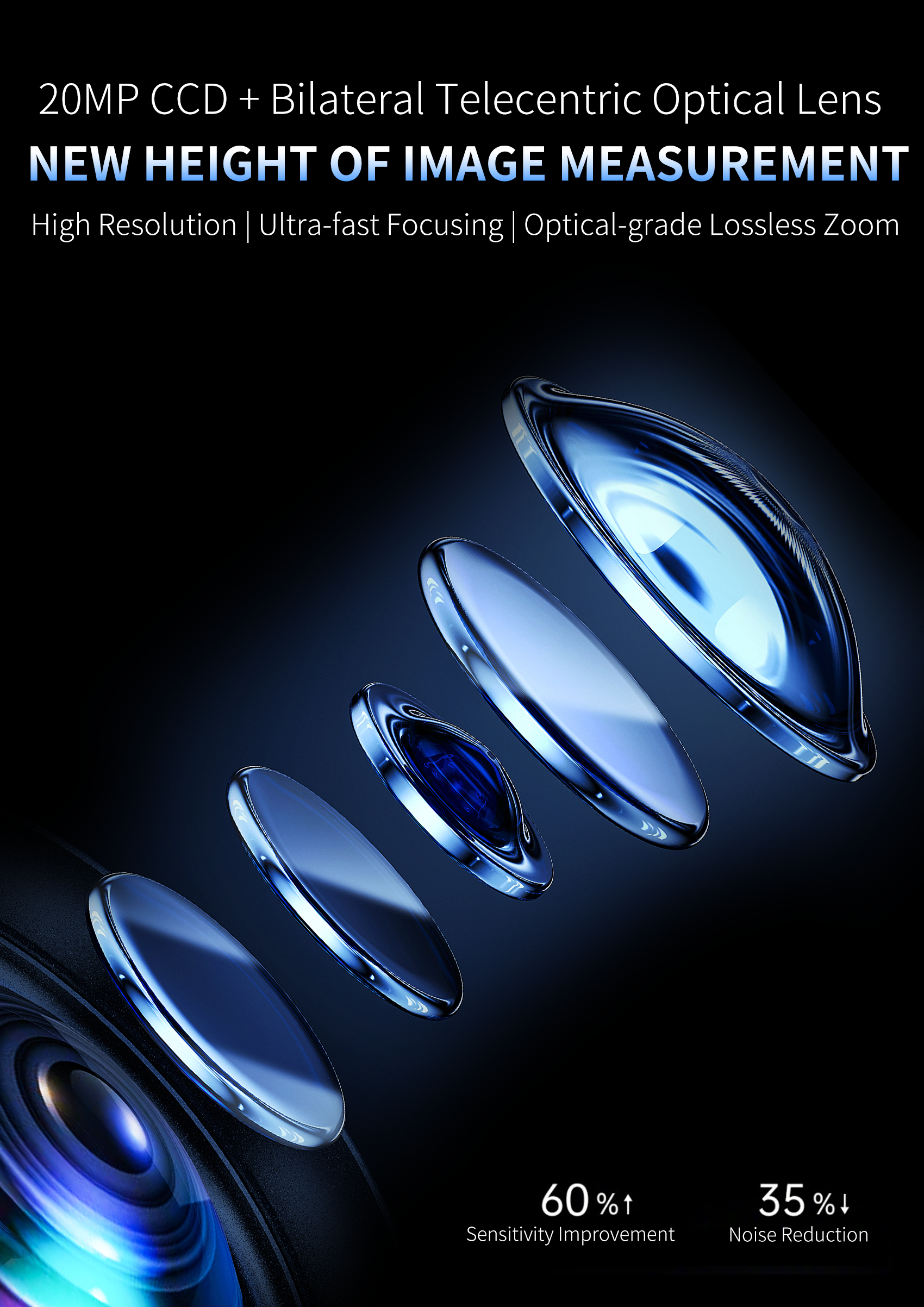

8.20MP CCD + Bilateral Telecentric Lens-A New Benchmark in Image Measurement

High resolution, ultra-fast focusing, and optical-grade lossless zoom deliver exceptional clarity and precision.

8.20MP CCD + Bilateral Telecentric Lens-A New Benchmark in Image Measurement

High resolution, ultra-fast focusing, and optical-grade lossless zoom deliver exceptional clarity and precision.

9.Premium LED Illumination for a New Level of Brightness

Longer Lifespan · Energy-Saving · High Efficiency

Powered by JATEN’s self-developed programmable light source control system, it reduces energy consumption, lowers operating costs, and delivers stable, high-quality illumination.

9.Premium LED Illumination for a New Level of Brightness

Longer Lifespan · Energy-Saving · High Efficiency

Powered by JATEN’s self-developed programmable light source control system, it reduces energy consumption, lowers operating costs, and delivers stable, high-quality illumination.

10.COMPREHENSIVE SOFTWARE UPGRADE-Introducing the New DCRAD System

10.COMPREHENSIVE SOFTWARE UPGRADE-Introducing the New DCRAD System

11.Next-Generation Precision Imaging System

(1)Dual 20MP CCD Sensors

Two 20MP CCDs paired with the latest edge-detection algorithm enable automatic surface and contour measurement with high precision.

(2)Adjustable Light Source

Equipped with a built-in brightness sensor for automatic illumination adjustment, ensuring optimal visual performance in every measurement environment.

(3)Dual-Magnification Telecentric Lens

High-telecentricity dual telecentric optics with ultra-low distortion.

Images remain accurate with no deformation at height steps or edges, eliminating concerns about measurement position errors.

11.Next-Generation Precision Imaging System

(1)Dual 20MP CCD Sensors

Two 20MP CCDs paired with the latest edge-detection algorithm enable automatic surface and contour measurement with high precision.

(2)Adjustable Light Source

Equipped with a built-in brightness sensor for automatic illumination adjustment, ensuring optimal visual performance in every measurement environment.

(3)Dual-Magnification Telecentric Lens

High-telecentricity dual telecentric optics with ultra-low distortion.

Images remain accurate with no deformation at height steps or edges, eliminating concerns about measurement position errors.

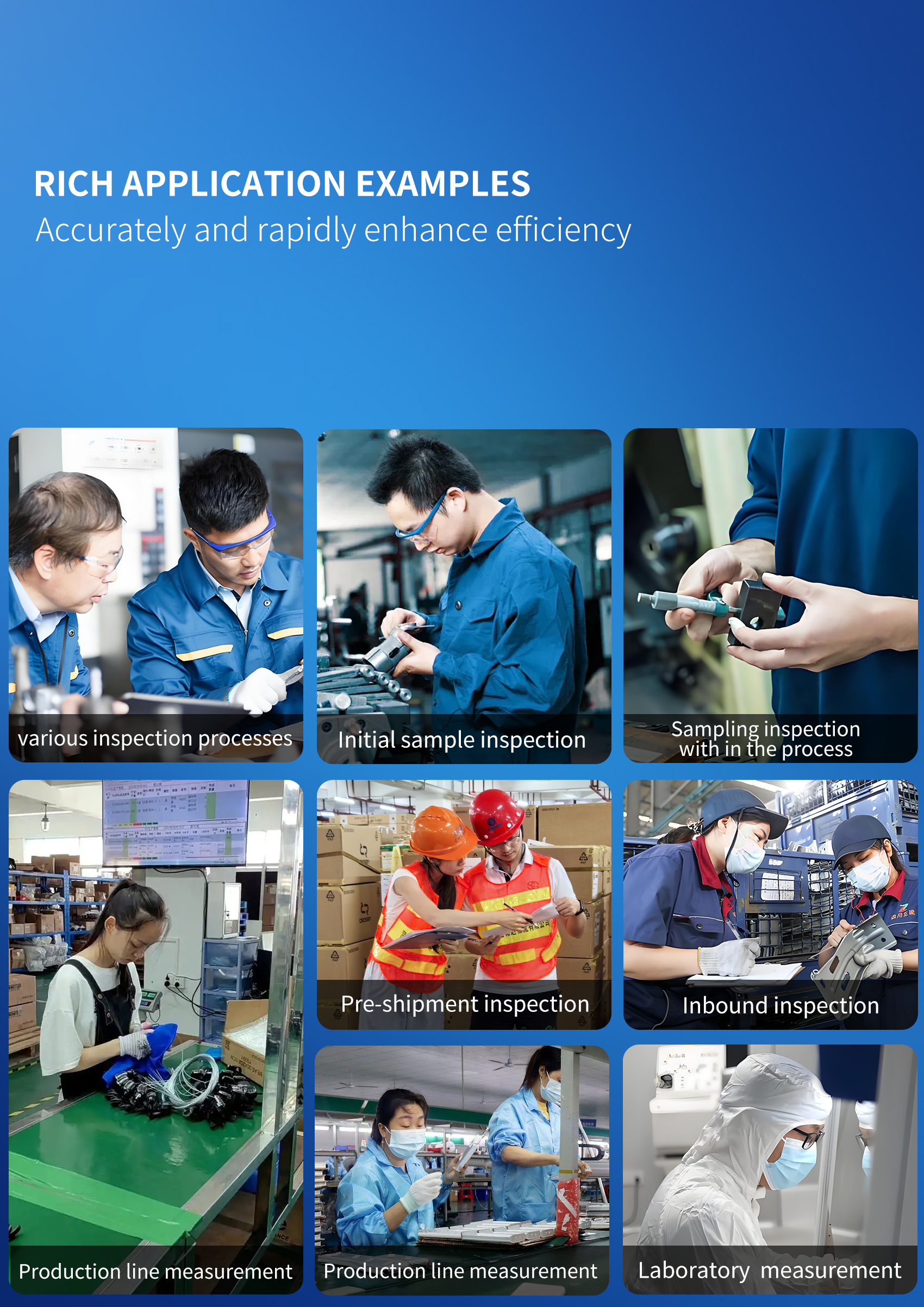

12.Rich Application Examples

Delivering fast, accurate measurements to significantly boost operational efficiency.

12.Rich Application Examples

Delivering fast, accurate measurements to significantly boost operational efficiency.

Description:

1. 330mm diameter screen with digital protractor;

2. 200x100mm precision movement work-stage, 300x200mm optional;

3. Work-stage sway range between 15°;

4. Halogen profile and fiber surface illumination adjustable;

5. Geometric multifunction data processing system DRO DP300;

6. Built-in Mini-printer;

7. Available 10x,20x,50x, 100x objective rotary table and foot-switch, etc.

- Q:What Is The Order Process? A: Inquiry – Quotation – Communication – Confirming – Deposit Payment – Production & Delivery – Assembly & Acceptance – After-sale Service&Maintenance.

- Q:Are You Trading Company Or Factory? A: We are Factory, 20 Years focusing on measurement and test instruments field with a store of experience. OEM is acceptable.

- Q:We Know Little About The Machine, How To Choose Correct Model? A: After get your demand, our professional team will work out best solutions by sending catalogue, specification, demonstration video or other methods according to customers’ need.

- Q: May We Visit Your Factory? A: Yes, We sincerely invite your team to visit our factory at your convenience; we’ll provide best service for you.

- Q: What’s The Delivery Term & Port? A: Normally, we have standard products in stock. If no stock, delivery time is 15-20 working days after deposit receipt. If urgent, we’ll try to make special arrangement. Various shipping method Shipping from Shenzhen Port.

- Q:How about the packing for machine, is it safely protected during transportation? A: We provide well wooden packing, it won’t be damaged. We’ve delivered many machines without damage.

- Q: How About the Service for Installation and Training? A: We’ll provide operating instructions and video of English version. If near our agent, the spot service is easier. Or we can send engineer to your country to finish installation and training; it takes extra cost like air-ticket and accommodation.

Reviews

There are no reviews yet.