INTRODUCTION

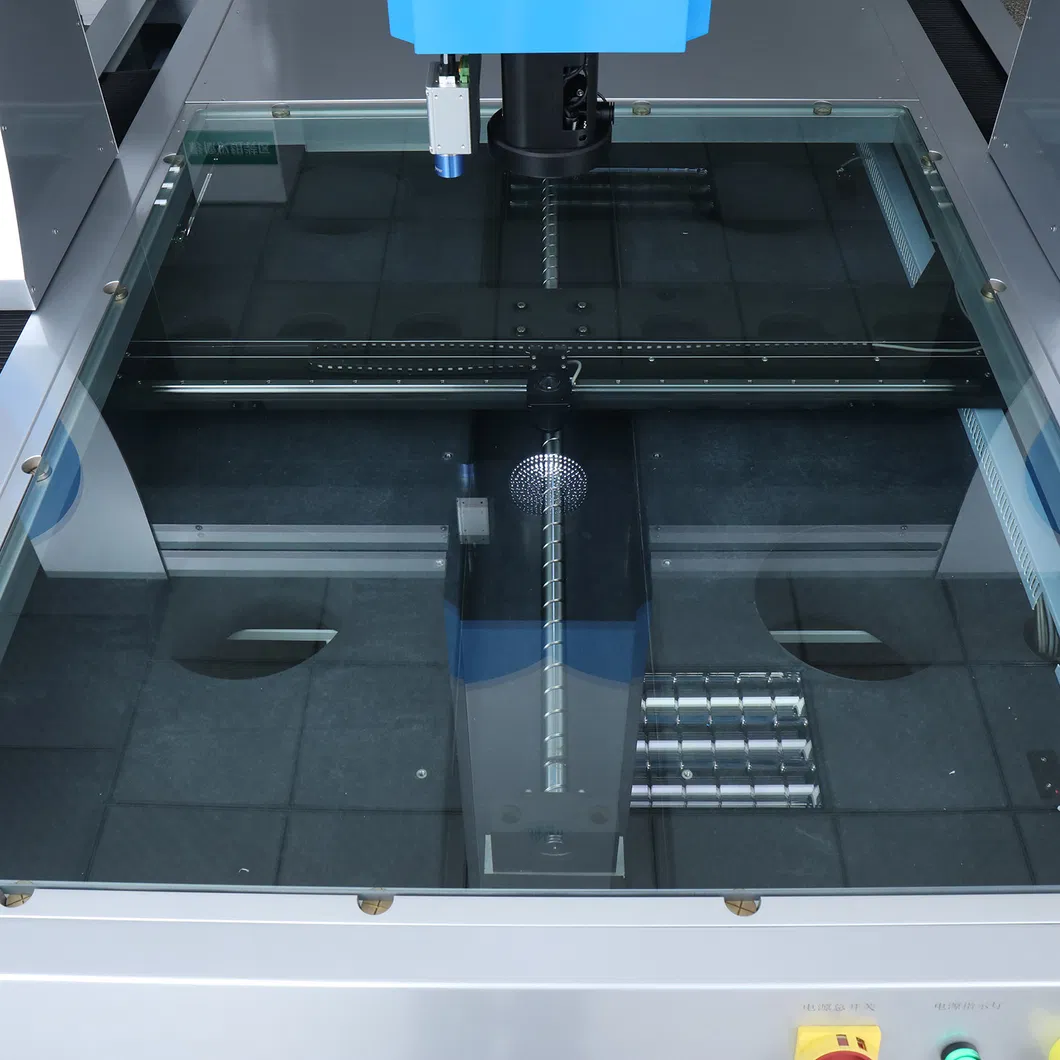

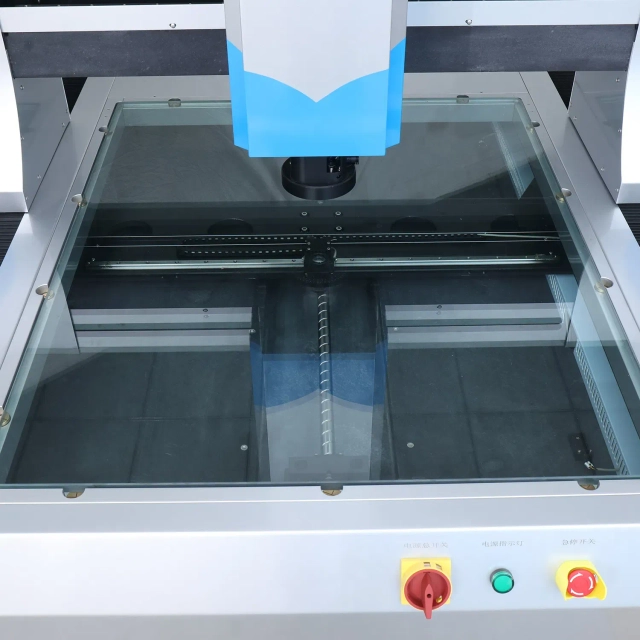

•The MV-series CNC video measuring system with a large horizontal structure which based on stable operating performance and a stable mechanism that does not deform.

•It is mainly used in industries such as PCB circuit boards, copper-clad laminates, flat glass, LCD molds, knife molds, and insulation materials.

FEATURES

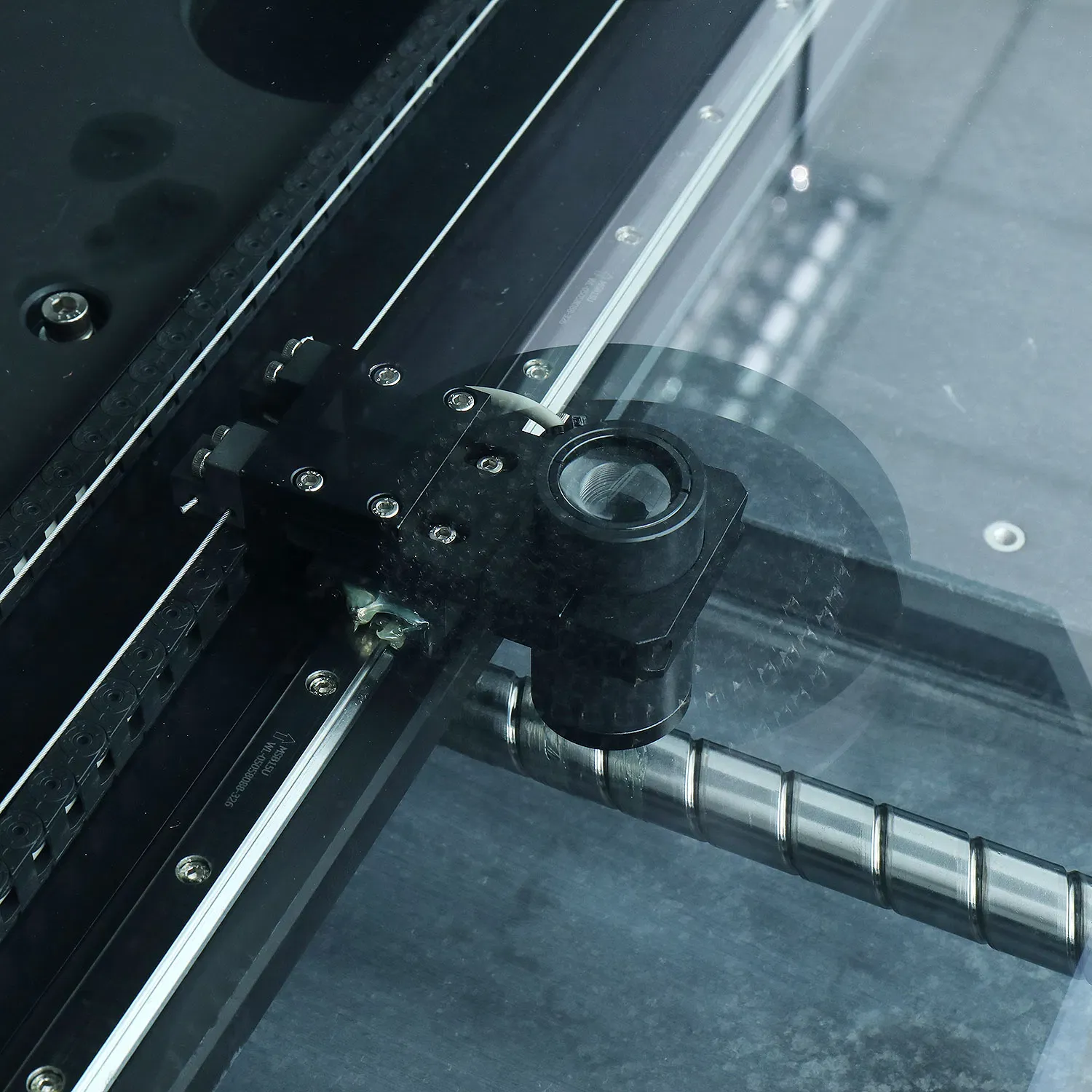

• Marble base&beam structure, in this structure, the work stage not moving i.e. the measured object not moving so when you do the high-speed measuring, it does not affect the measuring accuracy.

FEATURES

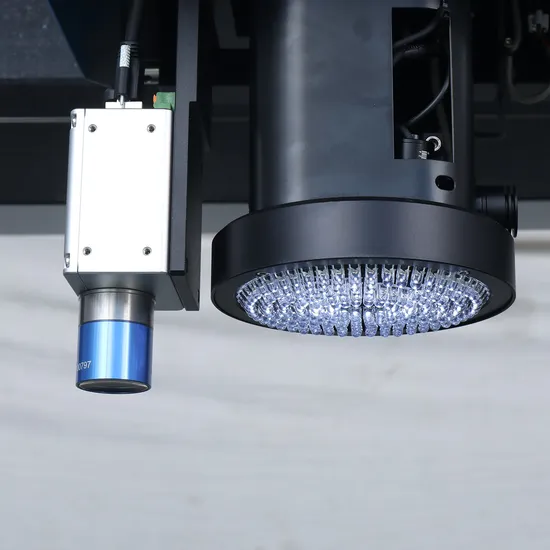

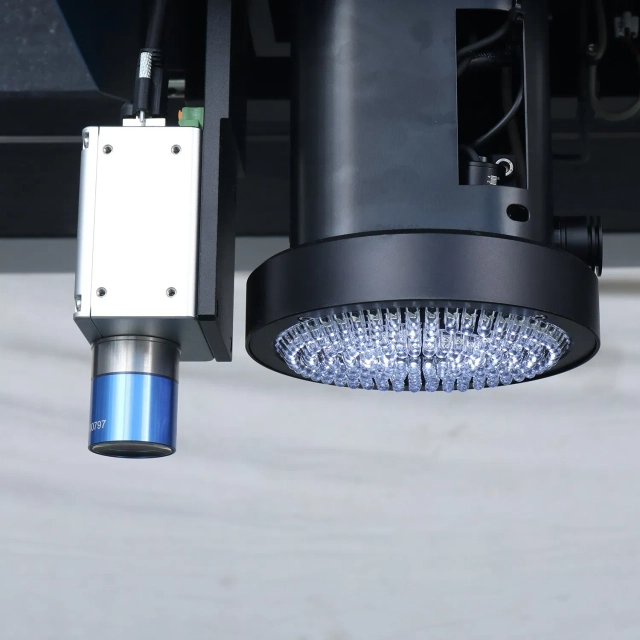

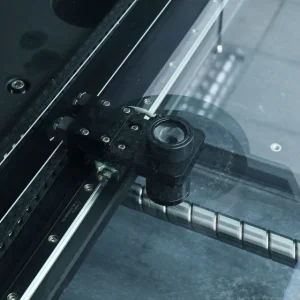

• High resolution 1/2″ color CCD camera and automatic Zoom lens with sharp images. after finishing automatic zoom, no need to manually re-calibration.

FEATURES

• Both the surface light source and the bottom light source use continuously adjustable LED cold light sources to avoid thermal deformation of the measured object

• Surface cold-light sourcezone controlprogramable

FEATURES

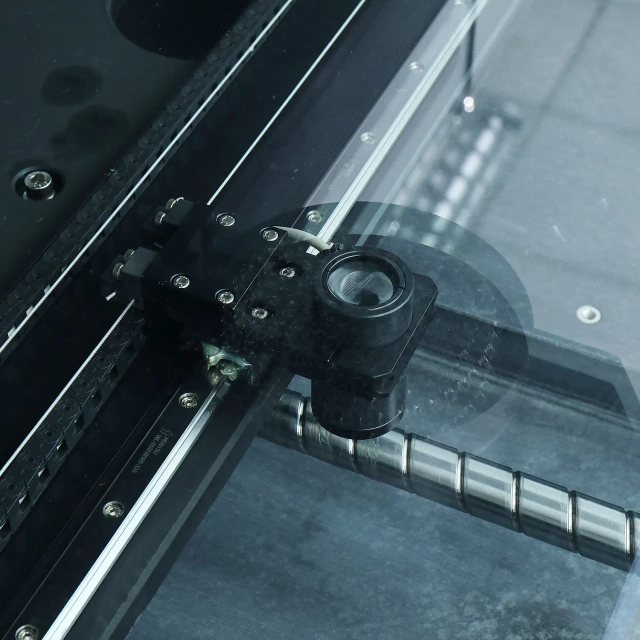

• The image navigation system allows you to quickly locate the measured accurate position of the measured object with the fast servo motor.

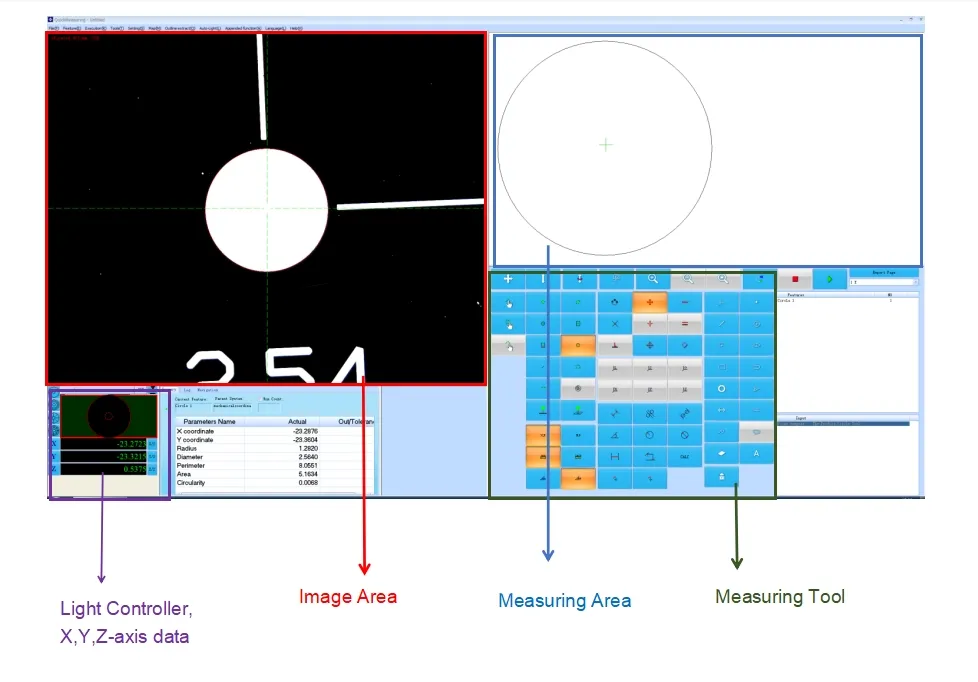

FEATURES(SOFTWARE)

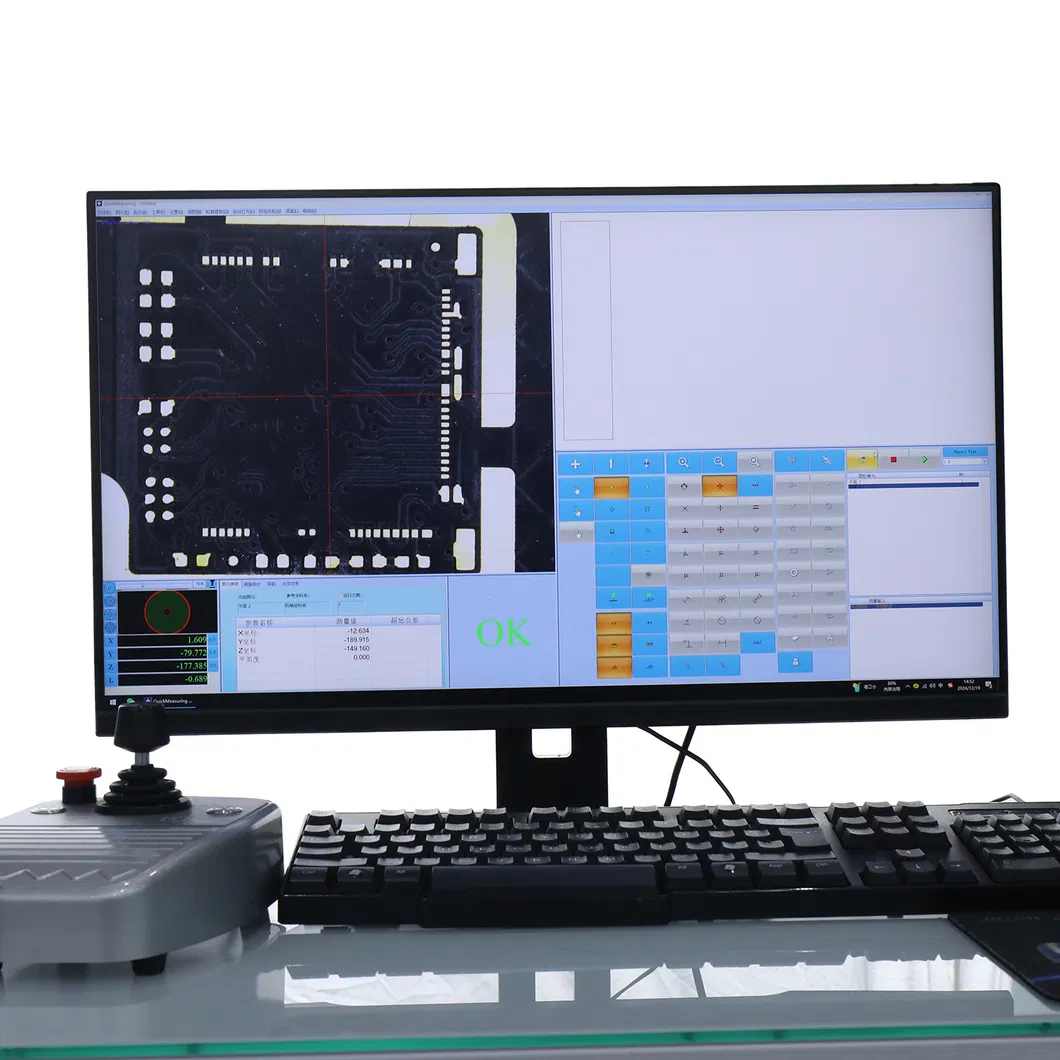

• Systems are Probe-Ready (optional), Auto focus function, joystick control and computer control. Applying Ms windows with CNC Quickmeasuring software ensures the best performance

•Automatic measurement software with ourindependent intellectual property rights JATENQuick-Measuring softerware is a programmable automatic detection System.

FEATURES(SOFTWARE)

JATEN Quick Measuring Software

Establishment of the coordinate system

Measurement of small and centrally symmetric workpieaces

• Element shape and tolerance

• Mgasuring 2D/3D elements

• DXF overlay and FOV capability

• CAD comparasion

FEATURES(SOFTWARE)

• User-friendly: Runs on Windows, easy to learn, integrates various functions for convenient use.

• Multi-geometry processing: Intuitive keys for accessing coordinates, dimensions, and views.

• Easy editing: Teach programming for automatic editing, saves and re-executes programs, imports DXF files.

• Auto result recording: Automatically saves, calculates, and recombines measurement data.

• Unit combination: Create new units from existing ones using function keys.

• Reference system: Set up and reset reference points; define multiple origins in one measurement.

Reviews

There are no reviews yet.